Innovating to Eliminate Plastic Packaging Waste - An Interview with Blue Lake Packaging

2022/03/30

This startup is a sustainable transformation partner for brands and manufacturers and strives to tackle the issue of plastic pollution in the packaging industry. Read to learn more about how they are working on their mission of preserving the natural environment for future generations.

Interviewer: Suzu Kitamura

Company Profile: Blue Lake Packaging

https://www.bluelakepackaging.com

Blue Lake Packaging empowers sustainable transformation for a future free of plastic pollution. With 100% fiber-based packaging solutions, Blue Lake Packaging creatively enables corporate citizens to reduce, and eventually eliminate plastic waste throughout the supply chain and product life cycle.

Ying Liu

Founder and CEO

Ying Liu, who holds degrees in engineering and business management, is an expert in supply chain management and corporate social responsibility. Before founding Blue Lake Packaging, Ying was a Senior Global Operations Director at Apple and was responsible for building Apple China Procurement and Operations from scratch. Such experiences and her passion for the environment position Ying perfectly to lead the push towards the use of sustainable packaging in manufacturing processes.

Plastic pollution has become a ubiquitous topic of concern on a global level, and for good reason. Every year, the human species produces around 300 million tons of plastic – a weight nearly equivalent to that of every person on Earth combined. And while recycling has been touted as the solution to the issue, only 9 percent of all plastic waste ever produced has been recycled, the rest of it ending up in landfills or in nature. Plastic, loved for its durability, never truly degrades but instead breaks down into tiny particles that now permeate the oceans, fish and animals, and even human bodies.

Ying Liu encountered the reality of plastic pollution in the packaging industry three years ago, when a friend asked her to find a company producing sustainable packaging. Based in China at the time, Ying thought this would be a relatively easy task, especially given her expertise in supply chains all around the world. However, after making rounds of calls and visiting numerous factories, she quickly realized that there were no packaging suppliers specializing in creating authentically sustainable alternatives to conventional packaging that meet the most demanding standards.

Later, Ying returned to the United States and visited a number of material recovery centers (MRFs) in the Bay Area. She was horrified by what she saw at these facilities: piles and piles of trash collected from households. “I saw that all of this trash was being sorted into different types of plastics. Materials recovery is a very market-driven business and only certain types of plastics have a market for recycling,” she tells us. “I realized that I never thought about where the trash I throw away actually ends up. I was faced with reality.”

*Material Recovery Centers (MRFs) are solid-waste management plants that process trash and sell recyclable materials to manufacturers, who then use those recyclables as raw materials.

Instead of turning a blind eye to what she had witnessed, Ying sprang into action, taking it upon herself to make a difference. Ying was no newcomer to the entrepreneurial spirit – during her time at Apple, she was sent to China to single-handedly set up Apple China Procurement, building the entirety of China procurement operations from scratch and handling every department until she found the right people. “I had to figure out how to hire people, find offices, even buy office supplies – all while managing every project. With limited resources, I found myself acting as the HR, IT, finance, and every other department. That was quite the entrepreneurial experience, although I was working in a big company.”

Capitalizing on her past experiences, Ying met with potential business partners with expertise in technology and biomass materials, finding others who shared her passion for the environment, and in 2018 successfully founded her startup Blue Lake Packaging: a one-stop shop for sustainable packaging solutions. “I felt like we had to do something to create what I call ‘exit-friendly’ packaging products,” she explains. “Products that are biodegradable, compostable and at a minimum, recyclable.”

Blue Lake Packaging uses biorenewable input materials as the ingredients for their products. The company sources fibers from paper mills around the world (China, Brazil, Norway, Finland) and utilizes materials such as bagasse (sugar cane waste) and bamboo as well. They also have their eyes set on eventually repurposing agricultural waste as input materials. However, for Ying and her team, producing truly sustainable packaging products is more than just using environmentally friendly inputs: “Blue Lake Packaging’s definition of sustainability addresses the entire lifecycle of the packaging product. Of course, our input materials are biorenewable, and we ensure that our manufacturing processes use the least amount of energy and water, and are free of toxic chemicals. But what differentiates Blue Lake Packaging is our focus on what happens when the product exits the value chain.”

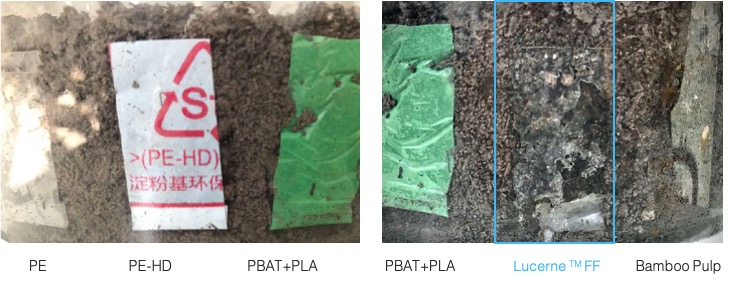

Take Blue Lake Packaging’s LucerneTM Fiber Film (LFF) for example, the film offers similar features and functionalities as its plastic counterpart does. However, LFF’s superior biodegradability, brought by its 100% natural fiber recipe, makes the whole difference. When LFF exits the value chain, it can either be recycled with paper, industrially or home composted based on what’s locally available. Even if it is left in the environment, it takes as little as 3 months to fully biodegrade and decompose while all its plastic counterparts, including bioplastics, remain intact.

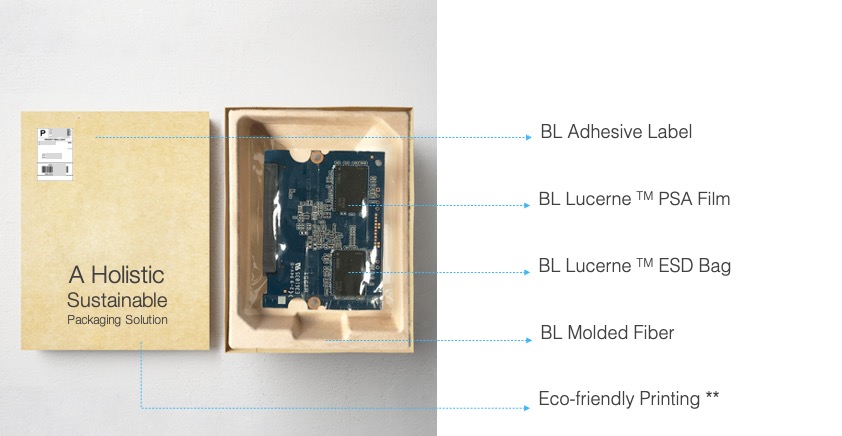

Ying also stresses that manufacturers should be conscientious about the entirety of their manufacturing processes – including the packaging that is used when transporting components and work-in-progress items. During her years of managing suppliers and supply chains, Ying has seen firsthand the market opportunity that exists here. “There are definitely many materials in that process that I think can be more environmentally friendly, which I see as a market opportunity for sustainable packaging. The entire value chain should be environmentally friendly, including the packaging used within the supply chain. We would like companies to think beyond just the packaging of their finished products.”

Blue Lake Packaging offers an impressive range of alternatives to replace every kind of packaging, ranging from transparent and protective films to fiber foams. The company works with manufacturers to develop bio-based solutions for specific needs. One example of an industry they have broken into is the automobile industry. “There are a lot of protective films on a new car – the body of the car, the dashboard, and the windshield. Those films are not actually recyclable in many cases, but we provide an alternative that is compostable,” Ying says.

Another specialty of the company is their electrostatic discharge (ESD) protection packaging. In fact, Ying sees a potential opportunity in the Japanese market for this specific product. “Japan is home to a lot of electronics manufacturing that is very advanced compared to other countries. With environmental protection in mind, our ESD packaging solutions could be a good fit. We’re definitely interested in working with Japanese brands and manufacturers to take advantage of the technologies we have and helping them reduce plastic waste.”

The electronics industry is not the only reason Ying sees great market potential for her company in Japan, but the people and culture as well. “Based on my knowledge of the Japanese lifestyle and market, I feel there are a lot of people who are very conscientious about the environment, are sensitive about what kind of materials they’re using, and very diligently recycle and compost. That mentality and lifestyle is a good fit for the type of products Blue Lake Packaging is offering.”

Blue Lake Packaging is revolutionizing the packaging industry, not only through its focus on exit-friendly products, but also its emphasis on the importance of being eco-conscious at all stages of the manufacturing process. The company has unlimited potential, but with that comes challenges. For one, the sheer number of opportunities for a sustainable packaging company can be a challenge in itself, Ying says. “It’s a matter of how quickly we can produce solutions or launch new products. I see so many opportunities out there that we can pursue to make a difference. Our team spends a lot of time doing research, but we are a relatively small startup so we have to pick and choose the opportunities we can realistically pursue.”

Another difficulty for the company has been the travel restrictions that have come with a global pandemic; with a team of 20 members split between two countries, Ying tells us that being restricted to online communication with her Suzhou team and partners has been difficult.

Yet another challenge for Ying is balancing parenthood and entrepreneurship. “I want to be a good role model for my kids and show that we have to strike a balance between life and work, as well as the personal goals and impact we want to have. These are very important to me.” And as a parent, for Ying, the vision of Blue Lake Packaging – a plastic pollution-free environment for future generations – is personal. “I’m very concerned about what my two small kids will experience when they are my age. Maybe they won’t be able to find clean soil anywhere. Or maybe they won’t be able to find clean ocean water.”

What all of us – companies and individuals alike – can learn from Ying’s story is the importance of taking initiative and addressing the pressing issues we see around us. If not us, who? If not now, when?