Creating new air value by utilizing cutting-edge technology that enables real-time detection of allergenic substances | Sensio Air x Daikin Industries Case Study Interview

2022/08/03

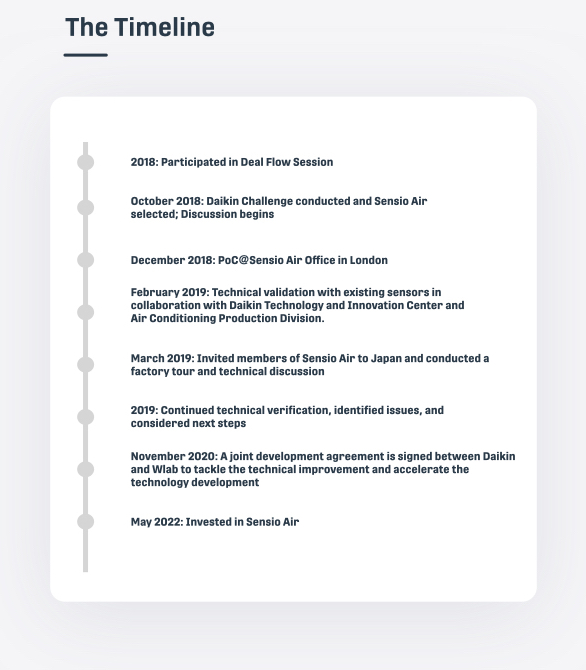

Daikin Industries, Ltd. (hereinafter “Daikin”) has been working to create air conditioning solution businesses that realize safety and reliability in indoor air qualities and spaces. They set “Promotion of Solutions business connected with customers” and “Creating value with air” as key strategies in their strategic management plan “FUSION25”., Daikin hosted a project called “Daikin Challenge” with Plug and Play in 2018 to search for collaborative partners from a wide range. Through the Daikin Challenge, Wlab Ltd. (hereinafter “Sensio Air”) was selected to start working with Daikin. Sensio Air provides products that monitor, detect and identify allergens in indoor environments in real-time using AI and IoT, as well as applications for users.

To learn more about the background of the collaboration, we conducted an interview with the people who participated in this project.

Writer: Megumi Shoei

Communications Manager

Mr. Takashi Namikawa

Senior Engineer, Group Leader, Analysis and Evaluation Technology Advancement Group, Technology and Innovation Center

*As of May 2022 when Daikin announced the investment in Wlab Ltd.Takashi Namikawa joined Daikin Industries in 2006 and engaged in product development at the Chemical Research and Development Center. In 2018, as a group leader and senior engineer, he led the advancement of analysis and evaluation technology for air conditioning, chemistry, environment, among others. In 2021, he also took on the role of lead researcher at the Research Association for Advanced Systems (RaaS).

Mr. Hideo Katayama

Technology and Innovation Center, Analysis and Evaluation Technologies Group

*As of May 2022 when Daikin announced the investment in Wlab Ltd.Hideo Katayama joined Daikin Industries in 1983. He worked on the commercialization of hydrogen peroxide electrode blood glucose meter as a new business at Shiga factory. In 2011, he was temporarily transferred to Nippon Muki Co., Ltd., where he measured the distribution of allergen levels in the air environment and the removal effect by filters. Currently, he is focusing on promoting joint research in industry-academia collaboration.

Mr. Shotaro Maeda

Technology and Innovation Center, Analysis and Evaluation Technologies Group

*As of May 2022 when Daikin announced the investment in Wlab Ltd.Shotaro Maeda joined Daikin Industries in 2018. At Technology and Innovation Center, he is engaged in the development of mold, pollen, and virus measurement and sensing technologies as part of the advancement of analysis and evaluation technology for air conditioning, chemistry, and the environment, and so on. In the efforts with Wlab, he is promoting the project as a bridge person.

Mr. Tasuku Nango

Technology and Innovation Center, Technology and Innovation Strategy Office

*As of May 2022 when Daikin announced the investment in Wlab Ltd.Tasuku Nango joined Daikin Industries in 2008. He engaged in technological development and demonstration testing of advanced energy management systems, including remote monitoring systems for air conditioners and demand response systems. In 2015, he was relocated to Silicon Valley, U.S., where he was in charge of technology scouting and startup co-creation support, and returned to Daikin headquarters in June 2022.

Mr. Cyrille Najjar

Sensio Air, Inc. CEOCyrille Najjar is a CEO of Sensio Air (Wlab ltd), a healthcare analytics and biotechnology company that specializes in particle and allergen identification, symptom prevention and prediction. The company focuses on AI, hardware, and healthcare. The company has won multiple prizes for its technologies. Cyrille is a member of the Board of Advisors at Cambridge’s Carbon 13, Nearcast, Click NFT, Tresor Track, and Pixie Foundation. As a teaching fellow at UCL and a Honorary fellow at Cambridge University, Cyrille has been teaching, product development, innovation and spatial design for over 14 years. After working as an instructor at Google Launchpad, Techstars and Conception X, he is now delivering his workshops and leading Start X the startup program of Stanford University.

Dr. Eve Tamraz

Sensio Air, Inc. Co-Founder and Chief Scientific Officer of Sensio AirEve Tamraz graduated from the Ecole Normale Supérieure de Paris where she wrote a thesis on the neuronal interactions during early development. Eve also has a scientific background in Toxicology, Health and Environment. Her interest in cutting-edge technology led her to specialize in Synthetic Biology, an emerging research area at the convergence of advances in chemistry, biology, computer science, and engineering. She was recognized as a top innovator by the MIT technology review and listed in Forbes 30 under 30 Europe. She is now an ambassador of Allergy UK and focuses all of her time on bringing high-end laboratory equipment to the end users in order to simplify allergy and asthma prevention.

Encounter with unique technology that enables real-time detection and analysis of allergenic substances

ーーCould you tell us about the background of this collaboration?

- Tasuku:

The very first Daikin Challenge, held together with Plug and Play in 2018, was designed to select partners for technologies and areas that we would like to acquire and explore in the future. It involved the Air Conditioning Manufacturing Division which is the Product Development Unit, Technology and Innovation Center, and senior management team.

As a goal, we scoped to take on the challenge of detecting allergens, which the industry has not been able to achieve to date, as a means of further connecting with customers and solving their problems in order to capture future demand for new and updated air conditioning systems. In the selection of the Daikin Challenge, we thought that Sensio Air was a very attractive candidate. Normally, it takes one to two weeks for the analysis of allergenic substances to be verified after submission to a testing laboratory, but among many startups we explored, Sensio Air has the one and only technology that enables real-time measurement, which we found very appealing, so we decided to start collaboration with them.

- Shotaro:

Sensio Air’s technology was very unique and attractive, but we needed to confirm whether their advanced technology could be applied to our products, so we first conducted a technical verification.

To be specific, we tested whether Sensio Air’s technology could detect Japan-specific allergens, such as pollen from cedar and cypress trees, and mold.

As a result, we concluded that their technology is essential to realize safety and reliability in indoor air quality and air environments, and decided to invest in Sensio Air to further accelerate our collaboration.

ーーWhat makes Sensio Air’s products so unique?

- Cyrille:

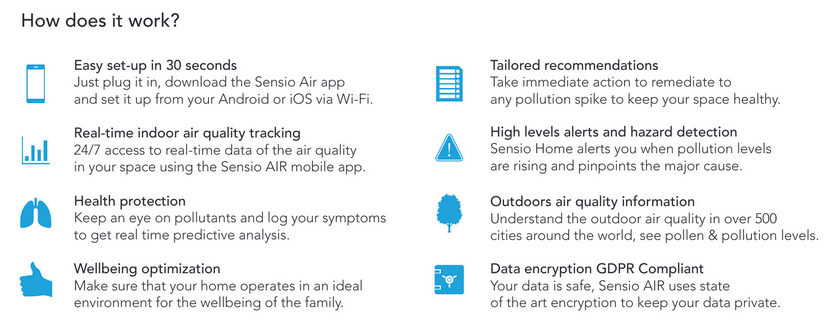

We have a technology that enables us to differentiate particles in real-time when they’re floating in the air. We also monitor. Pollen and pollution information from 320 cities across the world, not only pollen, mold, dust, mite, and dander, but also subcategories such as Japanese Cedar pollen from American Cedar pollen or dog dander from cat dander. The service is offered in a variety of products with a mobile application, where you can monitor the data, log your symptoms, and check indoors and outdoors levels.

We also offer an Air Care kit that can be deployed in your home or office. It is a sampler for up to three rooms that you can order and ship it back. Once we run the analysis, you can receive your personalized report and advice from experts.

Our main product, Sensio Air, runs 24/7 continuous analysis of your air and returns 72 analysis per day, so once every 20 minutes for particles and another every 4 minutes for gasses, CO2, temperature, humidity, VOC and so on. Now we’re currently working on a fourth version of the product for its integration into appliances.

(Provided by Sensio Air)

ーーHow is it possible to verify allergens in real-time?

- Cyrille:

We’ve offset the technical loads of the detection to the cloud. Essentially, our device harnesses data and then the cloud does the analytics. The typical allergen analysis commonly done today requires a researcher to put a sticky tape out for a week and then takes that tape and looks at it under a microscope, does a comparison, and then gives you the past week’s reading. This takes about two weeks and is awfully antiquated. We combine science, technology, cloud computing, and hardware to produce analytical results within seconds.

The process of collaboration and the challenges they encountered

ーーCould you elaborate on the collaboration process from meeting with Sensio Air, verifying the technology, and investing in the company?

- Shotaro:

As a result of the technical verification, we thought that technical improvements were necessary, so we refined the technology together through joint development and expanded the scale of testing step by step.

Alongside the technical verification, we also acquired field data while utilizing one of Sensio Air’s products, Air Care kit, to investigate the health effects of allergens on the human body.

- Takashi:

When we were refining the technology, members of the technology development team at our headquarters and Sensio Air members held a web meeting once every one to two weeks to have in-depth discussions. Since the existing business division was indispensable for commercialization, members of the Air Conditioning Manufacturing Division and key persons from various sections were also involved in the technology development.

- Eve:

We were used to having joint developments and collaborations with large companies, but I believe Daikin is one of a kind and the best one to understand the startup culture. Our team integrated with the Daikin team because the communication was very fluid and we had a team size of about 10-12 people working together, including all of our engineering, machine learning, and science team.

(Createdy by Plug and Play Japan)

ーーHow did you get various Daikin’s members involved in the process of collaboration?

- Takashi:

I think our corporate culture has a lot to do with it. We are a company that can produce results quickly by involving members across departments. In my case, I contacted directly the members I need to get cooperation from, even if they are in different business divisions. I guess it depends on a company, but if the company has sectionalism and they do not interfere with each other, it might be harder to get the company members involved.

I also believe that executives’ involvement is important to engage other divisions at an early stage. We made efforts in terms of communication to provide input about the progress and intermediate results to them regularly, at least once a quarter or every half a year, so that they could see the future potential of the project.

ーーDid you encounter any difficulties or challenges during the collaboration process? How did you tackle those challenges?

- Shotaro:

This was the first time for me to collaborate with a startup with a small number of people, and I found it a bit difficult until I recognized the difference in development process compared to Daikin. So I changed my mindset and switched the approach from the traditional “demand-based” style to “working with Sensio Air to create technology together” mode. We closely discussed how we could work together including how to utilize Sensio Air’s valuable resources. As a result, the speed to move the project forward has been accelerated.

- Tasuku:

In terms of communication, we were careful to clarify the claims and opinions of both sides, and I tried to bridge the gap between the two companies.

- Takashi:

I was always conscious of not leaving things up to the other party. In collaboration, both companies have their standpoints, so while respecting each other, we made it a point to hold regular meetings. To maintain close communication, I think it was very important to have an online meeting once every two weeks or so, regardless of whether we didn’t have specific agendas to talk about.

ーーThis is Sensio Air's first collaboration with a Japanese company. What did you bear in mind to overcome the language barrier, time difference, and difference in speed?

- Cyrille:

I think “Be patient” is the keyword in all of this.

Regarding the language barrier, both language and the way of thinking are fundamentally different between the U.S, the U.K. and Japan. It is important to communicate profusely to promote mutual understanding, while structuring things and expressing the same idea from multiple angles to best make your point across.

Also, we used a lot of charts and visual data to present information. So this helped the scientific research and the collaboration go smoothly.The speed difference between startups and large companies is always a big challenge, but speed, repeatability, and reliability, when you put all three together, suddenly speed becomes less important than repeatability and reliability. So, it’s true that startups start building things that scale faster than larger companies. However, if you want to become a company that grows over 20-30 years and more, you need to input these other parameters and speed sometimes needs to be reduced, as the quality goes up and that’s what we learn as a startup when we work with a large corporate, because they cannot afford to make unreliable products to risk their reputation. To gear into their way of work is something that we appreciate.

- Eve:

I believe a very big part of the success of this project was Tasuku and the team and having someone from Daikin seem to take the time to try to understand the startup’s point of view and make the link between the two entities. This, in my opinion, was a very, very big part of why this project was successful. Tasuku was someone who could follow up on both sides. So he understood the needs of the startup and the needs of Daikin so linking the two made the collaboration very easy on our site.

ーーWhat are some of the lessons that both companies have learned through this collaboration that will lead to future success?

- Hideo:

As the technology has improved through the joint development agreement, we would like to keep continuing to verify the effectiveness of the technology. Daikin hopes to enter the phase of exploring the new air value that can be created by combining our technologies and products with Sensio Air’s one to see how airborne allergens in the actual living environment change when our air purifiers are used.

- Eve:

We had a specific database that would detect around when we first started 50 different allergens at the beginning phase of the product development. Through the joint development project with Daikin, we needed to add specific Japanese allergens to our database. So after that collaboration, we were able to detect Japanese Cedar and cypress, and many other location-specific allergens. Also, another ongoing project is to investigate the allergen loads in Japanese homes. We are doing testing with a collaboration of Daikin and by sending our kits to Japanese homes to understand what type of allergens are in the air throughout the year. To my knowledge, this is the first time that this kind of data has ever been observed. I believe it’s a very big milestone between our company and Daikin but also on a scientific level, so we’re planning on publishing a scientific article. These are milestones that we took with Daikin and we wouldn’t have done alone.

- Cyrille:

I think the Daikin team has been extraordinary, very focused, and determined. I appreciate that there’s something very similar between the startup and the company that’s been around for about 100 years. It is the fact that they have to think long term and they have to never stop improving, and the Kaizen mentality is fundamental. We found this from Daikin and it was a great fit for us. We were very happy to see that they deeply understood continuous improvement and innovation.

I think one of the big takeaways and potentially what you’re gearing towards as a success is to be able to work with a multibillion-dollar company to integrate our solutions and enhance the product of a larger company. I guess this would be a great milestone of success for a startup like us.

ーーWhat is your vision for the future?

- Takashi:

Through the past co-creation activities with Sensio Air, we have come to be able to build up together on realizing to develop Sensio Air’s unique allergen sensing technology for practical application at Daikin. We will now enter the phase of testing the technology in the marketplace and move on to field evaluations and PoCs for commercialization.

We will continue strengthen our collaboration with Sensio Air and accelerate the creation of a new air conditioning solution business, and we are determined to strengthen the creation of a safe and secure air environment by combining air quality diagnosis and ventilation/sterilization technologies to achieve our growth strategy themes of “Promotion of Solutions business connected with customers” and “Creating value with air.”

We believe this is the starting point for our company, and we would like to aim higher with Sensio Air.

- Cyrille:

We’d like to be fully collaborating with Daikin on multiple verticals. We think there’s a big opportunity in the market because we’re the only one right now who can deliver such precision over the identification of allergens. Daikin has a very large fleet of devices they deploy every year, and to be able to integrate those, which require us to be the most reliable possible. We’ll see what we can achieve together.

Also, working with large enterprises is definitely helping us achieve our vision which is to be in every home, every space, and every office delivering to the customer with the understanding of the air quality, so that they can get the recommendations they need, but also take action to improve their quality of life, and do a lot of prevention and management of symptoms.

Contact us!

Plug and Play Japan supports the promotion of corporate innovation by matching promising startups with major companies. Plug and Play Japan members work with companies to help them improve operational efficiency, reduce costs, formulate new businesses, and other issues they face in order to realize open innovation.

If you are interested, please feel free to contact Plug and Play Japan.