Cleaner Water, Greener Products — How Algix Turns Algae into Sustainable Materials

2022/11/14

A Mississippi-based startup solves three environmental problems with one solution. Their technology named BLOOM captures CO2 in the air, replaces petroleum-based plastic with bioplastic, and cleans up polluted water environments to restore the natural ecosystem.

Interviewer: Chiyo Kamino

Communications Associate, Kyoto

Ryan Hunt

Founder and CTO

Holds physics and bioengineering degrees from the University of Georgia. Co-founded Algix with an interest in circular technologies involving algae, photosynthesis, and thermoplastic compounds. Successfully developed sustainable technologies combining environmental remediation and biomaterials under his own brand, BLOOM. His current projects includes collaborative initiative with governments and companies, in the aim to tackle air and water pollution problems.

The Beginning of Algix

ーー First and foremost, can you briefly tell us how you started your business?

Algix was founded in 2010, as a spinoff out of the University of Georgia. We were working on advanced biofuels, and using algae as a tool for environmental restoration. It is our mission to harness this massive untapped resource and use them to replace petroleum-based products as a sustainable ingredient used in consumer products such as shoes, footwear, sports products, and so on.

How It Works

ーー Can you explain how BLOOM works?

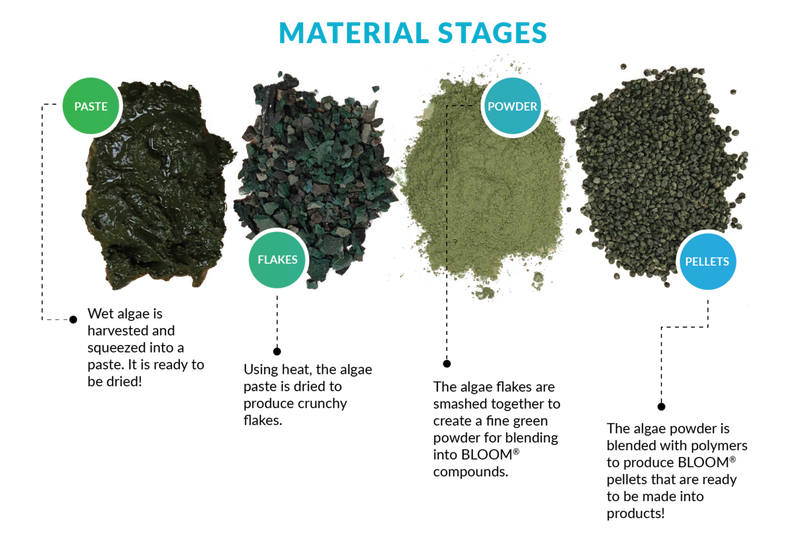

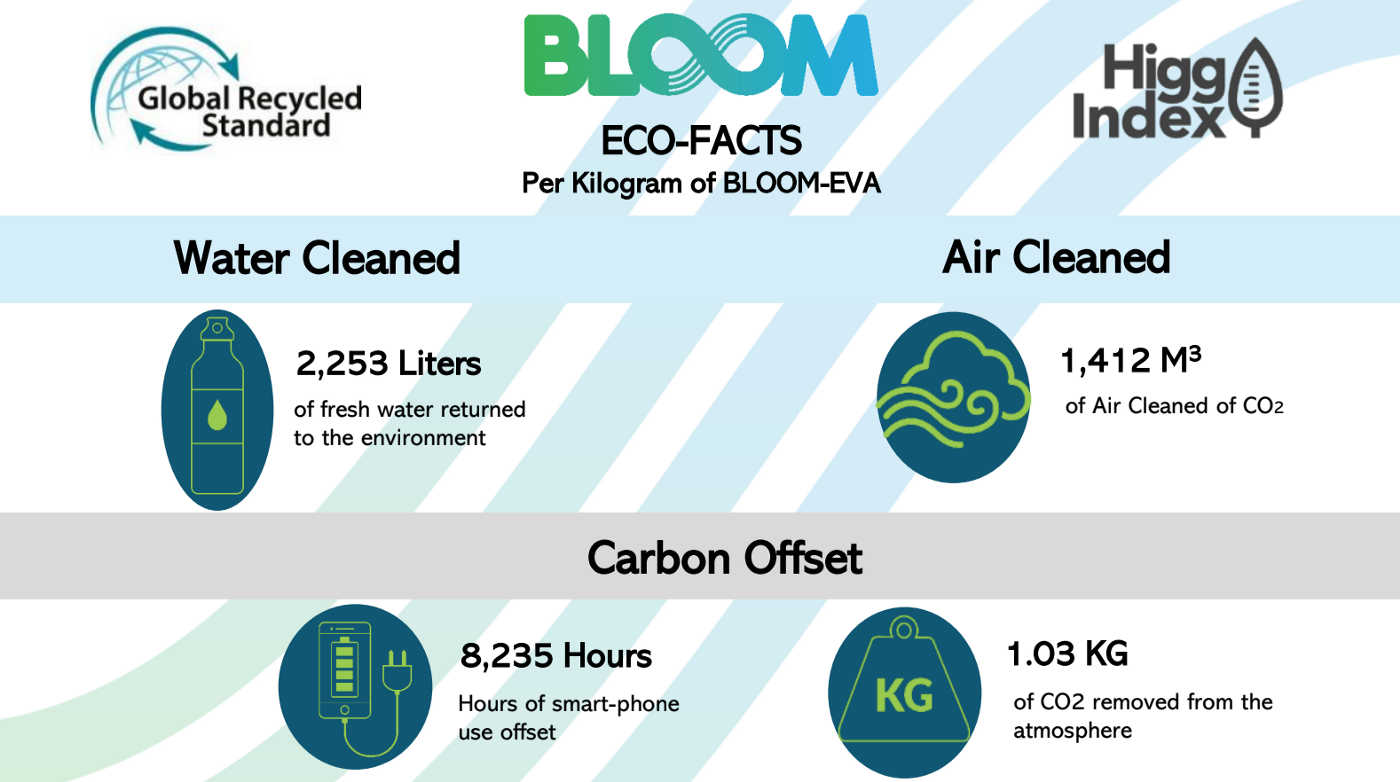

We blend raw algae biomass with base polymers, whether it be recycled polymers or biopolymers, or even engineered polymers, to produce thermoplastic compounds. In such a way, we can cut the usage of the base polymer by half. Once that algae gets incorporated in, we are now directly replacing a highly refined petroleum product that normally would require a lot of greenhouse gas emissions to produce.

There are massive lakes around the world that have been negatively impacted by water pollution which leads to harmful algae blooms. And those harmful algae blooms are capturing CO2 at an enormous rate. They can grow 10 to 100 times faster than plants and trees absorbing nitrogen and phosphorus. So by harvesting that algae and exporting it, drying it, and utilizing it, we can take advantage of essentially a problem and turn it into a solution.

(Photo Credit: BLOOM)

We work with partner factories all over the world. They use our product as a sustainable ingredient in the finished product. So a brand that makes, designs, and markets consumer products can say, “Hey, we’re trying to make our products better for the world, enabling and accelerating the adoption of new technologies, and new supply chains that don’t even exist yet.”

Right now we are focused on finding branded footwear and sports products. Mostly because they use the types of materials that we are familiar with. They use polymers such as EVA, rubber, or other polymers that we can incorporate algae into, so we have a lot of experience in making flexible foams. We have also done some traction pads, yoga mats, bicycle grips, and so on.

(Photo Credit: BLOOM)

Short Term vs Long Term Fix

ーー How do you manage sourcing, and how do you see the potential of scaling your business?

When we talk about sourcing, we are really talking about two approaches. One is to go downstream. We go into a lake full of algae, suck the algae out of the lake which negatively impacts the environment. That is a near-term fix. The long-term fix is going upstream to the city that is releasing those nutrients into the lake in the first place.

So we work with companies that deliver greenhouse-mounted photobioreactors that can clean water at a utility-scale. Other utilities are using open ponds with raceway paddles and high rate algal ponds. So there are different biotech solutions depending on where you’re at.

Every city has a wastewater plant, which is the source of all the raw materials that we need. Theoretically, every city can generate money instead of paying to treat your wastewater. What if the utilities are generating enough profit off of their mitigation of pollution? It’s flipping the entire industry upside down. The only way we are going to be able to do that is if we can leverage our technology as cheaply as possible. If we can find a clever way to turn it into something functional and usable, that’s gonna be the highest chance of being able to offset the pollution.

(Photo Credit: BLOOM)

Visions

ーー What is your vision for Algix?

We envision a new global supply chain where this aquatic biomass becomes a new agricultural commodity. If we are going to wean ourselves off of petroleum and fossil fuels, we need an alternative in the meantime — particularly with respect to building chemistry, making things like polymers and materials.

So there is a big opportunity to invest in the infrastructure that is required to transform our pollution: the wastewater and the CO2 emissions coming from industrial sources, such as power plants, wastewater facilities, industrial factories, even agricultural operations. We can actually use algae to directly remediate and transform that pollution into a valuable resource.

(Photo Credit: BLOOM)

Challenges

ーー What was the biggest struggle you have faced so far?

Creating a brand new supply chain that doesn’t exist has not been easy. But we have been very reliant on finding strategic partnerships with companies that have their mission to clean water. In the case of companies that are using algae as a wastewater treatment technology, that is the best-case scenario.

The other thing on the struggle side is, I would say the commercialization. It hasn’t been until 2017 that we started to see an increase in demand for our products. I think a lot of that has to do with understanding consumer demands and trends. Before that I didn’t think anyone was really willing to do it — it wasn’t quite there yet. We have kind of witnessed the evolution of sustainability within the footwear market specifically, where we are starting with one company in 2017. And now we have over 100 brands all doing it very quickly, that came on board. So that is exciting because it shows that the brands are really making a concerted effort to improve the sustainability of the products.

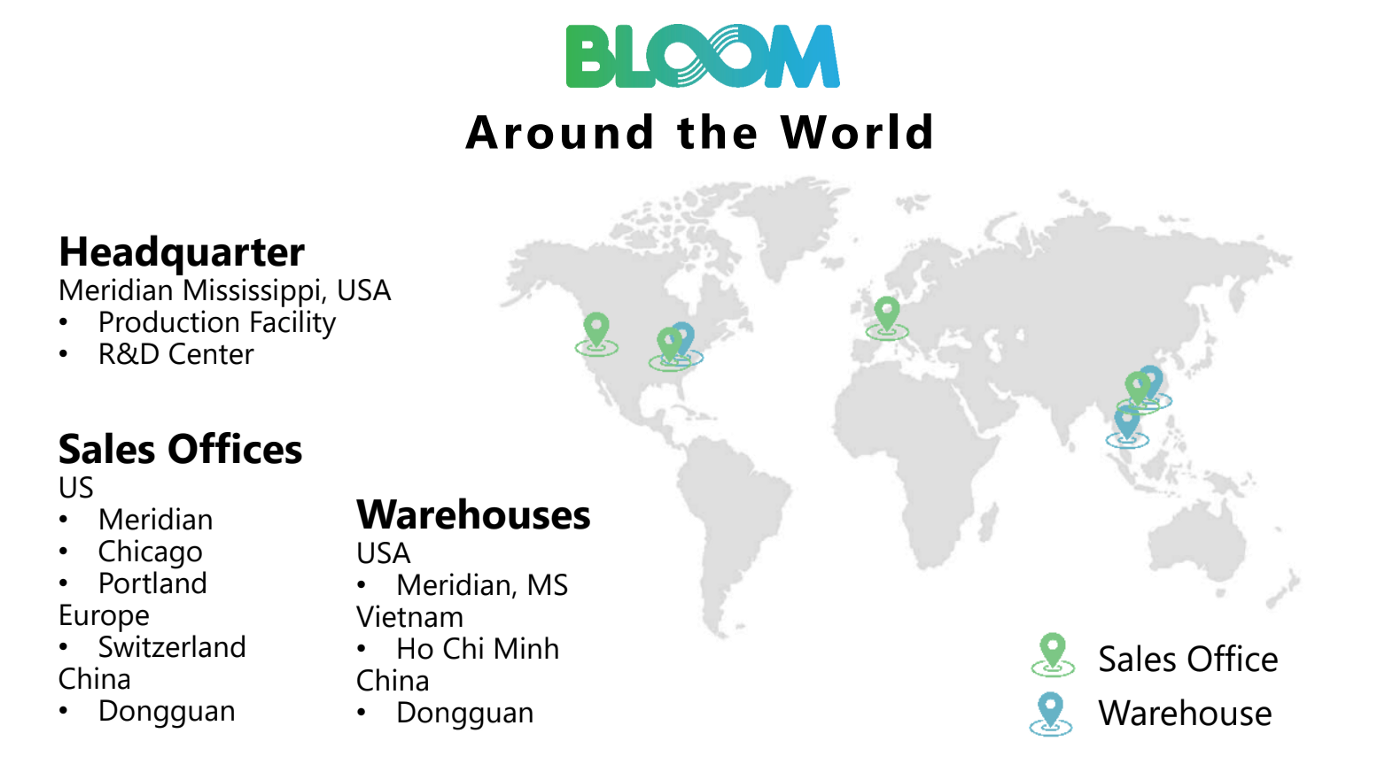

But it also has been challenging because when we deliver our pellets, we are not delivering finished shoes, just providing an ingredient into the shoes. So getting our product into the hands of the people who actually make the products is critical, thus we are working with Asian-owned footwear factories that are doing all of that. We were fortunate we have got a really good team built before COVID so we have been able to manage it even without needing to travel to China.

On Plug and Play’s Program

ーー Now that you are joining the Plug and Play’s program, what do you expect from potential partners in Japan?

For us, we are looking for strategic partners in Japan that have a corporate sustainability initiative as a part of their mission. A few of the companies that I’ve spoken with thus far have been related to green chemistry or packaging in consumer products. So the core goal of reaching out through Plug and Play has been to extend the ability to network with new companies, identify new brands, and understand the market landscape in Japan.

One thing that is really important for us is to align ourselves with responsible brands. Because, as our customers, when these consumer brands adopt our material into their supply chain, they’re helping us support these environmental protection projects. The fact that we can assign a $1 amount of value to a pound of dry algae is incredibly important to jumpstart this new sector.

Our materials have become quite popular within the footwear industry very quickly, and people know about BLOOM and other similar materials. But outside of that, I think it’s still relatively unheard of.

In fact, one of the reasons we focused on fashion was because the fashion industry as a whole has been much more mindful and willing to experiment to find better and more sustainable products and processes and to measure their impact on the environment. I think what started in fashion now is expanding out to electronics and other consumer products. In the not too distant future, all brands will have to talk about the environmental impact of their product or service with quantifiable metrics. The new generations are demanding transparency and the concept of circularity.

ーー As you mentioned, five or six years ago, nobody really saw the possibility of algal material but now it’s becoming popular. I hope some visionary companies in Japan can see the potential in your products as well.

That is really why we are looking to expand internationally. If this is going to be successful, every company, every country has to be aware of the sustainability of materials and processes that are available now.